Advanced Polymer Solutions • Precision Modification Technologies • Future-Ready Performance

CORE MATERIALS PLATFORM

Modified Engineering Plastics

| Material Type | Key Modifications | Performance Leap | Industrial Impact |

| Glass-Fiber Reinforced | PA66 + 30% GF | Tensile Strength: 180 MPa | 40% weight reduction vs. metal |

| Flame-Retardant Alloys | PC/ABS + Phosphorus System | UL94 V-0 @ 0.8mm | EV battery enclosures |

| Wear-Resistant Grades | PEEK + PTFE Lubrication | Coefficient of Friction: 0.15 | Medical implant longevity |

|Conductive Composites | PPS + Carbon Nanotubes | Surface Resistivity: 10³ Ω | EMI shielding for 5G |

Specialty Polymers Matrix

Molecular Engineering Excellence

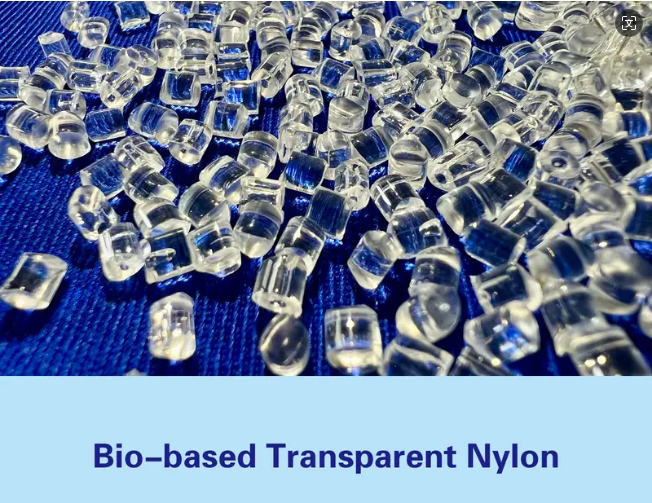

- Transparent Nylon (PA):

Nanoclay Modification → 92% Light Transmission + 30%↑ Impact Strength

- Long-Chain & Bio-Based PA (e.g., PA610/PA1010):

Castor Oil Sourcing → CO₂ Reduction 62% vs. Petro-PA

- Barrier Nylon:

Oxygen Transmission Rate: <0.5 cc/m²/day → 3X Food Shelf Life

- HT-PA (High-Temp PA):

Continuous Service Temp: 230°C → 25%↑ Auto Underhood Life

- PPSU/PEEK Super Polymers:

Hydrolysis Resistance → 3000+ Steam Sterilization Cycles

INDUSTRY-DRIVEN SOLUTIONS

Electric Mobility Revolution

- Battery Systems:

Flame-retardant modified PPS (CTI 600V) for cell separators

- Lightweighting:

40% Carbon-fiber reinforced PA66 charge ports (Replaces die-cast aluminum)

- Sensor Integration:

Chem-resistant transparent PA for LiDAR housings

Medical Breakthroughs

- Surgical Instruments:

Autoclavable PPSU (ISO 10993 compliant)

- Implant Tech:

Bio-inert PEEK-OPTIMA® with 3D-printed porosity

- Pharma Packaging:

Multi-layer barrier PA films (O₂/moisture blocking)

Sustainable Infrastructure

- Renewable Energy:

Glass-fiber modified HT-PA for hydrogen valve components

- Circular Economy:

Closed-loop recycled PA66 (95% post-industrial content)

- Ocean Tech:

Bio-based PA for marine corrosion-resistant fittings

FUTURE-TECH PATHFINDERS

Next-Gen Modification Tech

- AI-Driven Formulation:

Machine learning-optimized filler dispersion → 35%↑ fatigue resistance

- Nano-Functionalization:

Graphene-enhanced PEEK: Thermal conductivity ↑400% (15 W/mK)

- 4D-Printable Systems:

Shape-memory PPSU for self-assembling medical devices

Megatrend Convergence

| Global Shift | Our Polymer Response |

| Electrification | Dielectric modified PBT for 800V systems |

| Carbon Neutrality | ISCC+ certified bio-PA grades |

| Digitalization | Laser-direct-structuring (LDS) compounds |

| Advanced Medtech | Radiolucent PEEK with osseointegration |

TECHNICAL CREDIBILITY MARKS

◉ 200+ Material Grades with UL/ISO/FDA Certifications

◉ ASTM Test Data Verified by Third-Party Labs

◉ Global R&D Alliances: MIT Polymer Lab, Fraunhofer Institute

FOOTER TAGLINE

Where Molecular Innovation Meets Industrial Ambition

CALL-TO-ACTION

"Request Your Performance Validation Kit"

+8613054736186

+8613054736186

leave word

leave word